My K40 Laser Cutter

In the beginning of 2017 I came up with the idea of buying my own laser cutter. I do not remember exactly how I got the idea, but soon I saw a lot of possibilites for creating with such a machine. The ability to cut and engrave materials like wood, acrylic or leather sounded great for a tinkerer like me.

If you are not interested in the Laser Machine itself, you can also skip to the end of this page to see some projects I made with the laser cutter

I did a lot of research about lasers, since a laser this powerful can be really dangerous, especially for your eyes. Just a couple months later I got my K40 laser cutter. The laser has a power of almost 40W – a regular laser pointer for comparison usually only has 1mW (0,001W).

There are different kinds of lasers, this one is a CO2 laser. A CO2 laser usually uses a long water cooled glas tube, filled with gas. The laser beam created by the K40 Laser Cutter is infrared, meaning you can not see the laser beam. This makes it even more dangerous. This tube is hidden under the white cover on the back. The beam is directed by 3 mirrors which partially move with the gantry.

There are different versions of this laser availabl. One version has a potentiometer and an amperemeter to adjust the power. The other version has a digital control panel, but no amperemeter. I bought the analogue version with the potentiometer, but I soon upgraded to a digital control board, while mainting the amperemeter. Now I have the best of both versions, which allows accurate and easy setting of the power. Recently another upgraded version of this machine was released, which already has some of the following modifications.

It is important that the water temperature does not get too hot. If yu do not take care of this, the laser loses power and the tube can get damaged. To ensure the water temperature does not get too hot, I installed a temperature sensor, which displays the current water temperature. The displayed temperature can which can be seen at the image above.

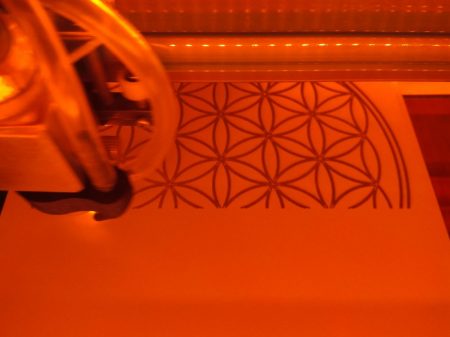

To see what is going on inside the machine I, added two led strips to light up the inside of the machine.

After a few weeks of using this machine I already was annoyed of the original clamp inside. The clamp is meant to hold the object which will be cut or engraved. For this reason I did some research and found a video where someone made a spring loaded bed, so the top of the work piece always is in focus of the laser beam. I really liked this idea so I took this idea and created my own version of a spring loaded bed.

Another modification is an adjustable laser head. This modification lets you set the focus point, which is really important. Together with the spring loaded bed I can easily adjust the focus point for different ticknesses of material. If you want to laser engrave a piece, you want the focus to be on the surface. If you want to cut a material though, you want the focus to be half the thickness below the surface.

Improving the cut quality:

To get clean and deep cuts an air assist is necessary. Therefore I use an airbrush compressor in combination with a 3d printed nozzle to blow air near the focus point. Additionally I installed an air pump to the laser head, which helps blowing away all the smoke and even keeps the lens clean, by blowing out the smoke. For routing the hoses for the air assist, I installed a cable chain to the back of the machine.

Another problem with a laser cutter is dealing with the fumes. The smell of wood is not that bad, but for example cutting acrylic smells really bad. For dealing with the fumes I installed a much more powerful extraction fan. From now on almost all the fumes vent outside and only very little smell enters the room.

To be able to cut when it is warm outside and the water temperature is too hot, I installed a few peltier coolers to decrease the water temperature. But to be honest this modification was not as effective as I was hoping. Better save some money and invest it in a proper water chiller.

So far those are all the major modifications I did to this machine. Even though the machine itself seems really inexpensive for what it is, but with all the modifications it also got much more expensive than I expected.

Want to get your own K40 Laser Cutter? You can find it here:

(If the version in the link should be out of stock, just search for K40 Laser and pick a different model)

Laser Cut projects

Here you can find some of the projects I did with my modified K40 Laser Cutter

This is one out of many box mods for my electric cigarettes I made. On this one I used the laser to cut the frame out of multiple thiner pieces of wood and glued them together. Also I engraved a design to the front panel. You can find many more picture of my box mods and other projects on instagram @modern_crafts

On this project I combined an existing product as well as my 3D printer and my laser cutter. I bought sunglasses, removed the glasses and designed and printed my own frame for them. Afterward I cut some walnut veneer and glued it to the front to give it a more interesting look.

Here we have another electric cigarette. This one is an Eleaf Istick 100. The mod was wrapped in veneer and later on engraved with the laser.

I bought a phone case online which had some recess for a fake veneer in it. After removing the fake veneer I added some real wooden veneer with an engraving of my motorbike.

Engraving the back side of a mirror, so you can see through and later on illuminated it from the back with some LEDs.

One more electric cigarette. I found an image of a cloud online and engraved it to one of the mods I bought. Even though this laser can not cut metal, it can remove the coating on this mod.

To have my electric cigarettes or the batteries, liquid bottles, drip tips etc more organized I used the laser cutter to cut a vape stand out of acrylic and assembled it with some screws and standoffs.

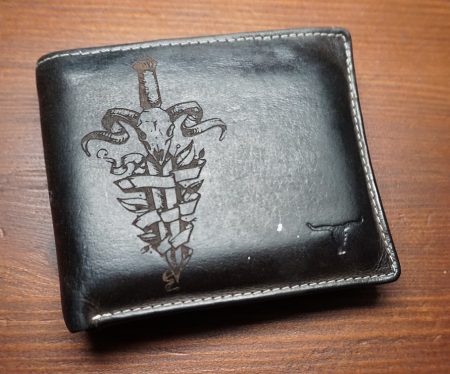

Since my wallet is made of leather I was able to engrave a picture to it.